Ikhwalithi engcono kakhulu engu-1000W/1500W/2000W/3000W Fiber Laser Welding/Laser Welder/Laser Cutting/Laser Cleaning Machine weStainless Steel/Aluminium/Brass/Copper/Carbon Steel

Sigcizelela intuthuko futhi sethula imikhiqizo emisha emakethe unyaka ngamunye ngekhwalithi engcono kakhulu engu-1000W/1500W/2000W/3000W I-Fiber Laser Welding/Laser Welder/Laser Cutting/Laser Cleaning Machine yeStainless Steel/Aluminium/Brass/Copper/Carbon Steel, Masibambisane sibambene ukuze sikhiqize ngokuhlanganyela ikusasa elihle elibonakalayo. Siyakwamukela ngobuqotho ukuthi uvakashele inkampani yethu noma usishayele ukuze sibambisane!

Sigcizelela intuthuko futhi sethula imikhiqizo emisha emakethe unyaka ngamunyeChina Laser Welding Machine kanye Welding Machine, Sinezisebenzi ezingaphezu kuka-200 ezihlanganisa abaphathi abanolwazi, abaklami abanobuciko, onjiniyela abasezingeni eliphezulu nabasebenzi abanamakhono. Ngokusebenza kanzima kwabo bonke abasebenzi kule minyaka engu-20 eyedlule inkampani yayo yaqina futhi yaba namandla. Sihlala sisebenzisa umgomo othi “iklayenti kuqala”. Siphinde sigcwalise zonke izinkontileka kuze kube seqophelweni futhi ngenxa yalokho sijabulela idumela elihle nokwethembana phakathi kwamakhasimende ethu. Wamukelekile kakhulu ukuthi uvakashele inkampani yethu.Sithemba ukuqala ubudlelwano bebhizinisi ngesisekelo sokuhlomula kanye nentuthuko eyimpumelelo. Ukuze uthole ulwazi olwengeziwe qiniseka ukuthi awunqikazi ukusithinta..

I-PARAMETER

| Amandla e-laser | 100W/200W/500W |

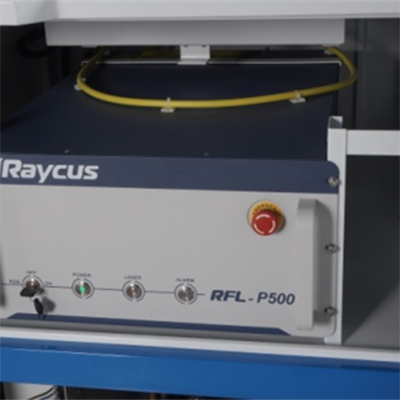

| Uhlobo lomthombo we-Laser | Raycus, IPG ongakhetha kukho |

| Laser wavelength | 1064 nm |

| Indlela yokupholisa | Ukupholisa amanzi |

| Amanzi okupholisa | Amanzi enziwe deionized |

| Izinga lokushisa lamanzi | 18-22 °C |

| Skena ububanzi | 10-60 mm |

| Igesi elisizayo | Umoya ocindezelwe/Nitrogen |

| Umfutho womoya | 0.5-0.8 MPa |

| Into yokuzikhethela | I-Handheld / Manipulator |

| Isimo sokusebenza | 5-40 °C |

ISICI

- Ukuhlanzwa kwe-laser okunembile ukuze uthole isikhundla esiqondile nosayizi oqondile.

- Ukusebenza okuguquguqukayo kwezingcezu zomsebenzi ezinokwakhiwa kwejometri okuyinkimbinkimbi kungenziwa ngekhanda lokuhlanza i-laser elibanjwe ngesandla.

- Isetshenziswa kakhulu endaweni eyisicaba, egobile futhi enezinhlangothi ezintathu ukuze kwenziwe ucezu lomsebenzi olunwebekayo kanye nepulasitiki enezimbobo ezincane nezijulile.

- Iphephile futhi ilungele imvelo. Ngaphandle kokusebenzisa okokuhlanza amakhemikhali noma ezinye izinto ezidlekayo

- Ukuhlanzwa okungeyena othintana naye futhi akukho monakalo we-substrate Kakhulu.

- Kulula ukuyisebenzisa, enemodi ephathekayo futhi ingafakwa irobhothi lokuhlanza okuzenzakalelayo

- Akukho kugcinwa futhi akukho okusebenzisekayo, akunathuli, akukho makhemikhali, akukho ukungcola.

- Izindleko eziphansi zokuhlanza kanye nokusebenza kahle kokuhlanza okuphezulu.

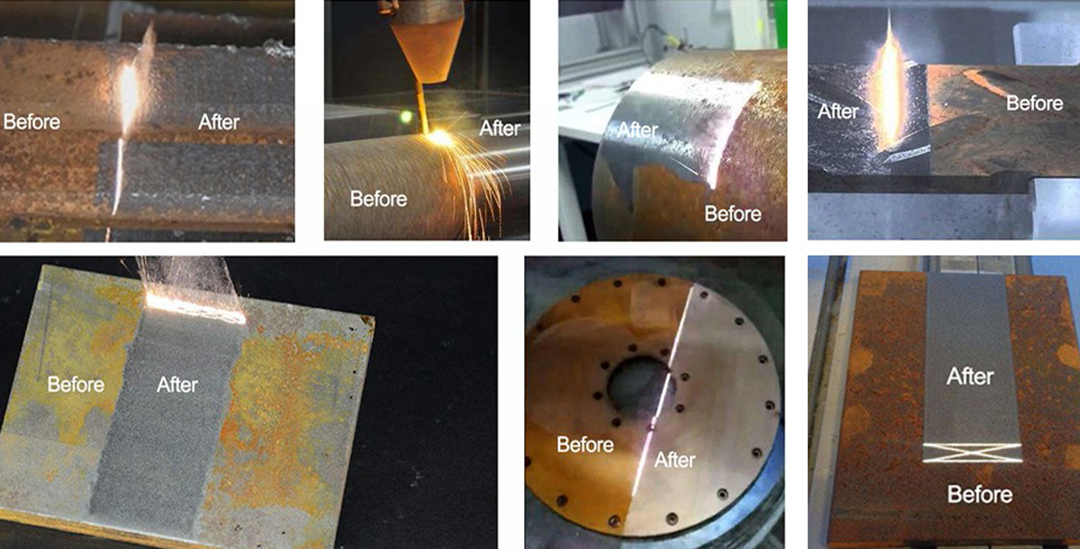

ISICELO

Ukususwa kokugqwala kwensimbi

Ukuhlanza upende ongaphezulu

Ukuhlanza ibala likawoyela ongaphezulu/ukungcola

Ukuhlanza indawo yokugqoka

I-Welding / i-coating surface ngaphambi kokwelashwa

Uthuli olungaphezulu kwesithombe setshe nokuhlanza okunamathiselwe

Ukuhlanza izinsalela zesikhunta sepulasitiki

IMINININGWANE

ISIMISO

Umehluko phakathi kwe-laser eqhubekayo ne-pulse laser yokuhlanza:

Ngemuva kokuhlanza ukukhanya kwe-pulsed, ungqimba lukapende olungaphezulu kwesampula lususwa ngokuphelele, bese kuvela ubuso besampula. I-Metallic white, futhi cishe akukho monakalo ku-substrate yesampula. Ngemva kokuhlanza ngokukhanya okuqhubekayo, ungqimba lukapende olungaphezulu kwesampula lukhishwe ngokuphelele, kodwa ingaphezulu lesampula libonakale limnyama-mpunga, futhi ingxenye engaphansi yesampula iphinde yabonisa ukuncibilika okuncane. Ngakho-ke, ukusetshenziswa kokukhanya okuqhubekayo kungenzeka kakhulu kubangele umonakalo ku-substrate kunokukhanya kwe-pulsed.

Kokubili i-laser eqhubekayo ne-pulsed laser ingasusa upende ebusweni bezinto ezibonakalayo ukuze kuzuzwe umphumela wokuhlanza. Ngaphansi kwezimo ezifanayo zamandla, ukusebenza kahle kokuhlanza kwama-laser ashaywayo kuphakeme kakhulu kunaleyo yama-lasers aqhubekayo. Ngasikhathi sinye, ama-laser acijile angalawula kangcono okokufaka ukushisa ukuze avimbele izinga lokushisa elidlulele le-substrate noma ukuncibilika okuncane.

Ama-laser aqhubekayo anenzuzo enanini, futhi igebe ekusebenzeni kahle ngamalaser ashaywayo lingenziwa ngokusebenzisa amalaser anamandla amakhulu, kodwa ukukhanya okunamandla aphezulu kunokufaka okukhulu kokushisa, futhi umonakalo ku-substrate nawo uzokwanda. Ngakho-ke, kunomehluko oyisisekelo phakathi kwalokhu okubili ezimeni zohlelo lokusebenza. Kuzinhlelo zokusebenza ezinokunemba okuphezulu, ukulawulwa okuqinile kokukhuphuka kwezinga lokushisa kwe-substrate, nama-substrates angabhubhisi, njengesikhunta, ama-laser ashaywayo kufanele akhethwe. Kwezinye izakhiwo ezinkulu zensimbi, amapayipi, njll., ngenxa yevolumu enkulu kanye nokushabalaliswa kokushisa okusheshayo, izidingo zokulimala kwe-substrate aziphezulu, futhi ama-lasers aqhubekayo angakhethwa.

Izinzuzo zama-laser pulsed:

Ama-laser ane-pulsed akhiqiza ukushisa okuncane, kuyilapho ama-laser aqhubekayo ekhiqiza ukushisa okwengeziwe, yingakho ama-laser anamandla amakhulu esebenzisa ama-pulses. Ama-laser ashayayo angenza ijeneretha ye-laser iphumule kancane, kuyilapho ukuvusa amadlingozi okuqhubekayo kungenza i-laser ngokuqhubekayo futhi ingaphazamiseki. umsebenzi, kulula ukufinyeza impilo ye-laser generator.

Isampuli