I-Fiber Laser Cutting Machine JZ1530EH

I-Voide

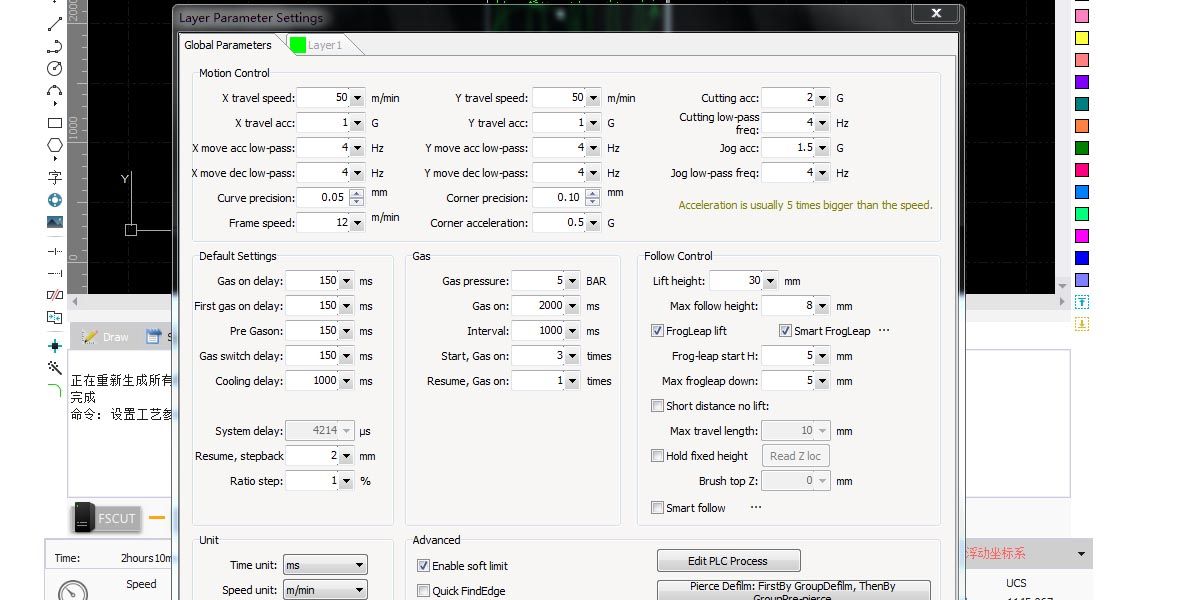

I-PARAMETER

| Imodeli | JZ1530 |

| Amandla e-laser | 1000---6000w |

| Isistimu yokulawula ye-CNC | I-Cypcut 2000E |

| Umthombo we-Laser | Raycus/Max/Reci |

| Ikhanda le-laser | I-Raytool BM110 |

| Shayela | I-Taiwan DELTA servo motors |

| Umnciphisi | I-Taiwan Faston |

| Ukudluliswa | I-Hiwin/SHAC I-Lean/APEX rack |

| I-laser lens | I-Raytool |

| I-valve elinganayo | Japan SMC |

| I-valve ye-Solenoid | Japan SMC |

| Ukusheshisa okukhulu kokusika | 2G |

| Isilinganiso sokulungiswa | 0.025mm |

| Hlela kabusha ukunemba | ±0.02mm |

| Imfuneko yamandla | 220/380V, 50/60HZ |

| Izinto ezisebenzayo | insimbi engagqwali, i-carbon steel, ishidi lika-galvanized, insimbi, i-aluminium, ithusi, ithusi |

| Igesi elisizayo | Umoya ohlanzekile noma i-Oxygen noma iNitrogen |

| Umfanekiso osekelwe | DXF,DWG,JPGE,PCX,AI,TIFF,PLT,CDR,BMP |

| Ikhompyutha enesofthiwe ye-laser yangempela | Umsebenzi we-WIFI uyatholakala |

ISICELO

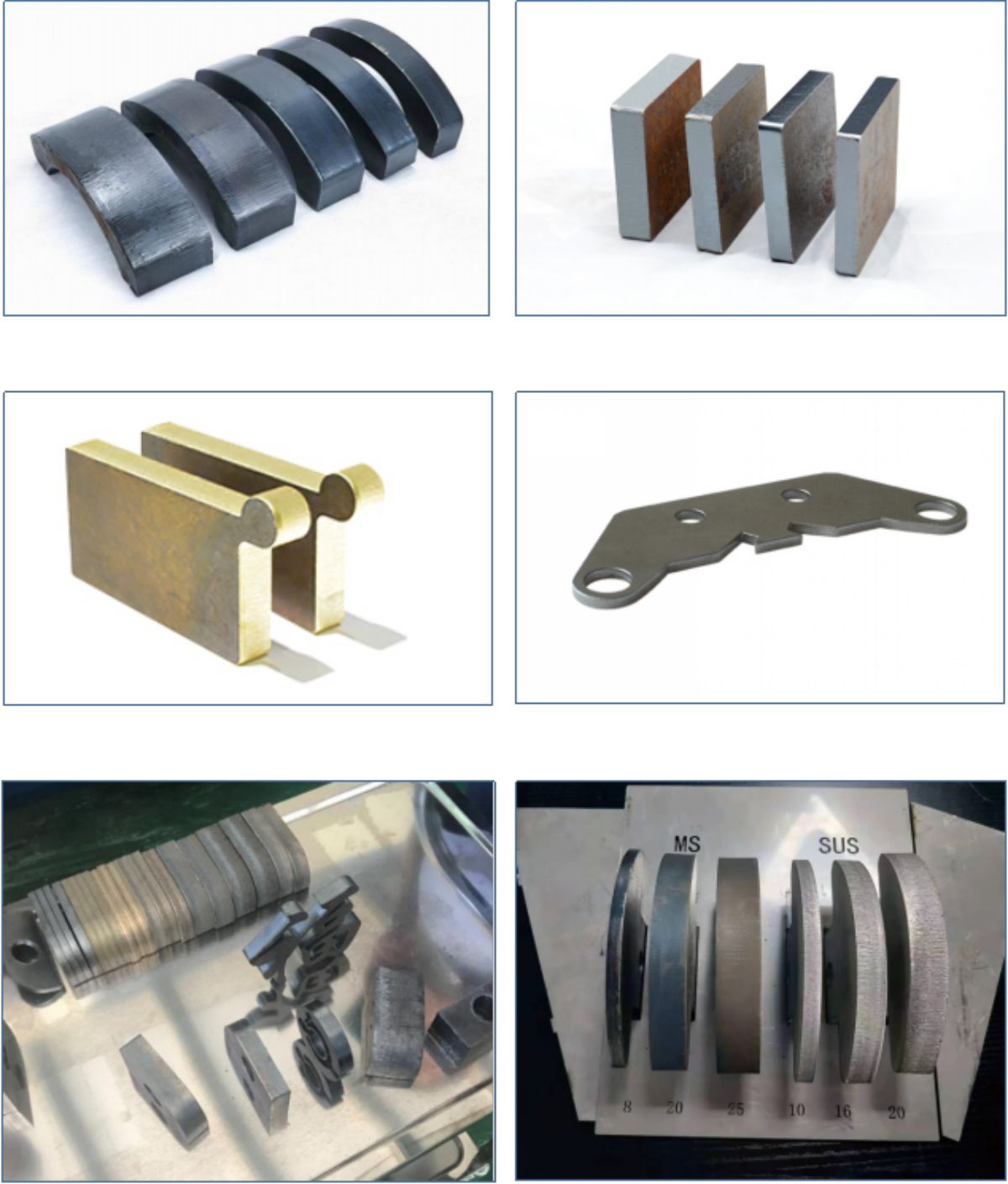

Izinto Zokusebenza: I-Fiber Laser Cutting Equipment ifaneleka ukusika insimbi ngeStainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Iron Galvanized, Galvanized Sheet, Aluminium Plate, Copper Sheet, Brass Sheet , I-Bronze Plate, I-Gold Plate, I-Silver Plate, I-Titanium Plate, Ishidi Lensimbi, I-Metal Plate, Amashubhu namapayipi, njll.

2.Izimboni Zokufaka Isicelo: Imishini yokusika i-JZ Fiber Laser isetshenziswa kabanzi ekukhiqizeni i-Billboard, Ukukhangisa, Izimpawu, Izimpawu, Izinhlamvu Zensimbi, Izinhlamvu ze-LED, Impahla Yasekhishini, Izinhlamvu Zokukhangisa, Ukucutshungulwa Kwensimbi Yeshidi, Izingxenye Zensimbi Nezingxenye, I-Ironware, Chassis, Racks & Ukucutshungulwa kwamaKhabhinethi, Imisebenzi yezandla yensimbi, i-Metal Art Ware, i-Elevator Panel Cutting, i-Hardware, Izingxenye Ezizenzakalelayo, Uhlaka Lwezingilazi, Izingxenye Zogesi, Ama-Nameplates, njll.ukuqinisekisa ukuthi ingasebenza ngendlela engenzeka ngesikhathi sokusika nge-laser.

IMINININGWANE

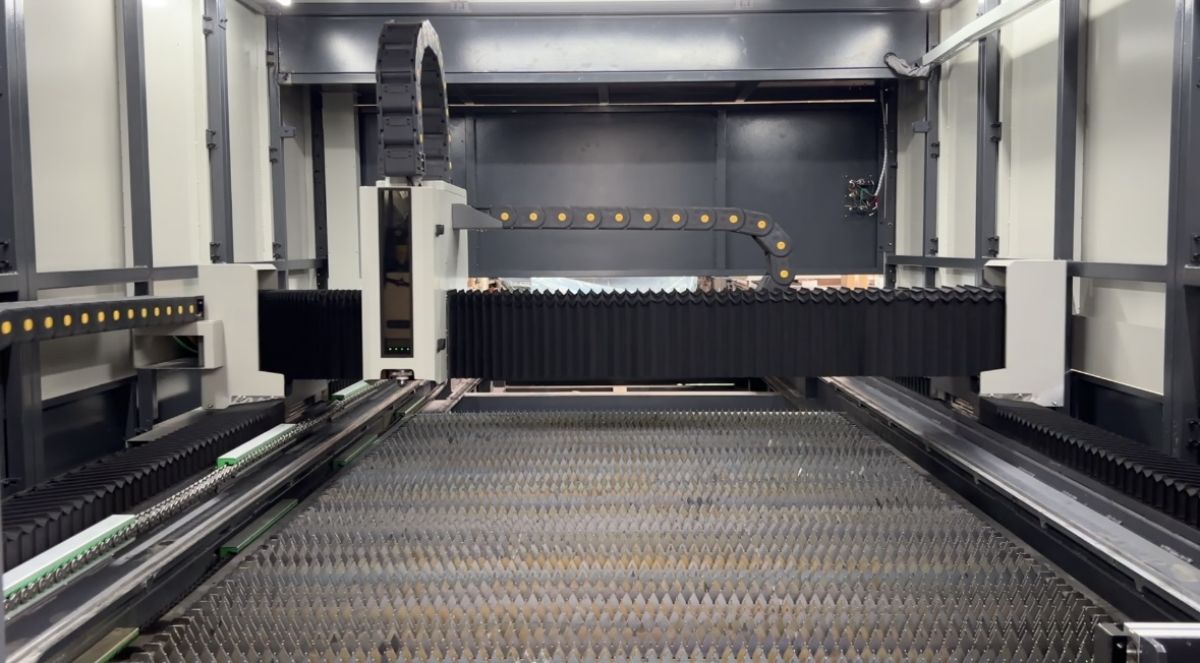

Isakhiwo Sombhede

Umbhede wenziwe ngepayipi elikhulu eliyisikwele eliwugqinsi bese ushiselwa ngokuhlanganyela futhi wakheke, bese wenziwa ukwelashwa kwe-stress annealing, ukwelashwa kokuguga kokudlidliza, ukuqeda kancane, kanye nezinqubo zokuqeda. Yonke inqubo ixazulula ngokuphelele inkinga yokuguqulwa kokucindezeleka okubangelwa ukushisela nokucubungula.

Imishini emikhulu yemishini ye-CNC engenisiwe isetshenziselwa ukugaya ngokunemba umbhede wonke, iqinisekisa ukunemba nokuzinza kombhede futhi inikeze amakhasimende isiqinisekiso esiqinile sesikhathi eside, inqwaba, nokusika okuzinzile.

Beam

I-beam yesiqephu esisodwa iyacinywa futhi igxiliwe ukuze kuncishiswe ukucindezeleka kwangaphakathi kanye nokuqina, ukulungisa izakhiwo zemishini ye-beam, futhi kuthuthukise ukuzinza kwe-beam.

I-Z-eksisi

Isikulufu sebhola le-Z-axis sishayelwa injini ye-servo ukubona ukunyakaza okuhambisanayo okuya phezulu naphansi kwekhanda elisikayo. Kunezindlela ezimbili zokulawula ezihambisanayo; ukufeza ukunemba okuphezulu ekusikeni kwe-laser, ikhwalithi yokusika ezinzile, nokuqinisekisa ikhwalithi yesigaba sokusika.

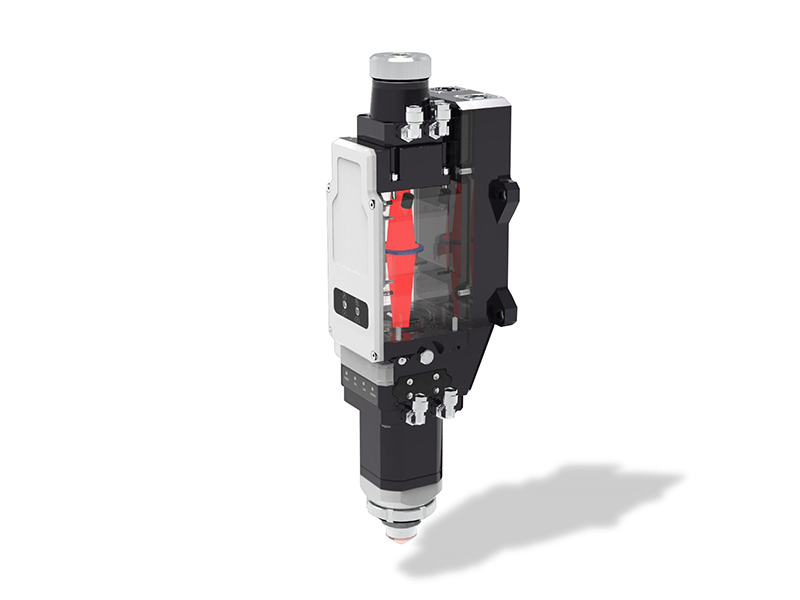

Ukusika Ikhanda

Ikhanda lokusika eligxile ngokuzenzakalelayo

Isixazululo esisha se-optical, ukugxila okuzenzakalelayo, ukunciphisa ukungenelela komuntu, ukupholisa umlomo wombhobho kanye nokupholisa amanzi enzwa kwenza ukusika kuzinze futhi kusebenze kahle. Akhelwe ngaphakathi amasethi amaningi ezinzwa, ukuqapha okuhlakaniphile kwesikhathi sangempela se-close-loop, ukuxilonga okusheshayo kwezinkinga kanye nesixwayiso sangaphambi kwesikhathi.

Umthombo we-Laser

Umthombo we-laser odumile, umthombo we-laser uhlanganiswe kakhulu, kulula ukuwusebenzisa, uncane futhi ulula, kulula ukuwufaka, ngokuyisisekelo awunakekelwa uma usebenza, unozinzo lokusebenza isikhathi eside nokuphila isikhathi eside.

I-Max Cutting Acceleration

Ukusheshisa ukusika kwe-2G Max, kuthatha isikhathi esifushane ukusuka ekusikeni ngesivinini esiphansi ukuya ekusikeni ngesivinini esikhulu, ukusika amakhona noma amaphoyinti okujika ngokushelela.

I-Smoke Exhaust System

Isiteji sokusika esivaliwe sithuthukisa ukusebenza kahle kokuhlanza futhi sinciphisa ukungcoliswa kwamalensi. Idivayisi yokukhipha intuthu izwa ngokuzenzakalelayo futhi ivule isikhipha intuthu esihlakaniphile, isikhipha intuthu esinamandla, kanye nokukhipha uthuli ngendlela efanele.

Ithebula Lokusebenza Elishintshiwe

Amathebula okusebenza aphindwe kabili angashintshaniswa ngesikhathi esifanayo, ukusika ipuleti lensimbi nokulayisha nokulayishwa kungenziwa ngesikhathi esifanayo, ukonga isikhathi sokulayisha nokukhipha; indlela yokudlulisa igiya kanye ne-rack izinzile futhi inembe kakhulu, futhi iphumelela kakhulu kunokudluliselwa kwe-sprocket chain evamile.

AMAsampuli