Ukuhlanza i-laser kanye nokucotshwa izindlela ezimbili ezihlukene zokwelapha izindawo zensimbi. Ukuhlanzwa nge-laser kuyinqubo yokwelapha indawo yensimbi esebenzisa i-laser beam ekhishwa ijeneretha ye-laser ukuze kukhiqizwe amandla aphezulu ukususa ukugqwala, ukuhlubula upende, nokukhipha okunamathelayo. I-Pickling iyindlela yokwelapha esetshenziselwa ukususa ukugqwala, amabala, ukungcola, noma ukungcola endaweni yensimbi.

Ukukha

Ishidi lokukhetha lenziwe ngeshidi eligoqelwe ngokushisayo lekhwalithi ephezulu njengempahla eluhlaza, futhi ungqimba lwe-oxide lususwa iyunithi yokukhetha, lunqunywe, futhi luqedwe. Umkhiqizo ophakathi phakathi kwamapuleti, ngesisekelo sokuqinisekisa ikhwalithi yendawo kanye nezidingo zokusebenzisa, wenza abasebenzisi bakwazi ukwehlisa ngempumelelo izindleko zokuthenga.

Pickling Amashidi Izinzuzo

1. Izinga eliphezulu lihle, ngoba isikali se-iron oxide esingaphezulu sisuswa ku-pickling plate eshisayo, ethuthukisa izinga eliphezulu lensimbi futhi yenze kube lula ukushisela, ukugcoba nokudweba.

2. Ukunemba okuphezulu kwe-dimensional, ngemva kokwenza isicaba, ukuma kwepuleti kungashintshwa ngezinga elithile, ngaleyo ndlela kuncishiswe ukuphambuka kokungalingani.

3. Ithuthukisa isiphetho esingaphezulu futhi ithuthukise ukubukeka.

Izinhlelo zokusebenza

Kungashiwo ukuthi i-pickling sheet iwumkhiqizo ongabizi kakhulu phakathi kweshidi eligoqiwe elibandayo kanye neshidi eligoqwe elishisayo. Inezinhlobonhlobo zezicelo embonini yezimoto, embonini yemishini, izinto zikagesi ezilula ezimbonini kanye nezingxenye zokugxiviza zokwakheka okuhlukahlukene, njengemishayo, imishayo engaphansi, amarimu, ama-spokes, amaphaneli enqola, abalandeli, izigubhu zikawoyela wamakhemikhali, amapayipi ashiselwe, amapayipi kagesi. amakhabethe, uthango, izitebhisi zensimbi, njll., zinamathuba emakethe abanzi. Ngezansi sizokwethula inqubo yobuchwepheshe yenqubo yokukhetha.

I-Pickling Principle

I-Pickling inqubo engaphezulu esebenzisa isisombululo se-asidi ukususa isikali nokugqwala ebusweni bensimbi, ngokuvamile kanye nokuqoshwa kwangaphambi kwesikhathi. Ngokuvamile, i-workpiece icwiliswa kwisisombululo samakhemikhali njenge-sulfuric acid ukuze kukhishwe ama-oxides namanye amafilimu endaweni yensimbi, okuwukwelashwa kwangaphambili noma ukwelashwa okuphakathi kwe-electroplating, koqweqwe lwawo, ukugoqa nezinye izinqubo. Okwaziwa nangokuthi ukuhlanza okumanzi.

Inqubo yokukhetha ihlanganisa ngokuyinhloko indlela yokucwilisa, indlela yokukhetha isifutho kanye nendlela yokususa ukugqwala kwe-asidi.

Ama-acids asetshenziswa kakhulu yi-sulfuric acid, i-hydrochloric acid, i-phosphoric acid, i-nitric acid, i-chromic acid, i-hydrofluoric acid nama-acids axubile.

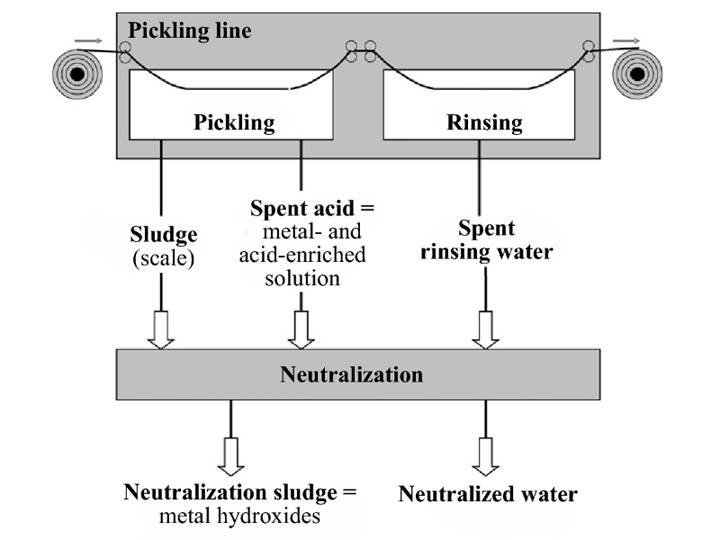

Ukugeleza Kwenqubo

Ukulengiswa ezingxenyeni zensimbi → ukususwa kwamakhemikhali (ukususwa kwamakhemikhali e-alkali okuvamile noma ukukhishwa kwe-surfactant) → ukugeza ngamanzi ashisayo → ukugeza amanzi agelezayo → isinyathelo sokuqala sokuqoqwa → Ukugeza amanzi agijimayo → Ukukhetha isinyathelo sesibili → ukugeza amanzi agelezayo → dlulisela inqubo elandelayo (njengaleyo njengalokhu: ukufaka umbala ngamakhemikhali → ukugaywa kabusha → ukugeza ngamanzi ahambayo → ukwelapha okuqinisa → Ukugeza → Ukwelapha Ukuvala → Ukugeza → Ukomisa → Kuqediwe).

Amaphutha Avamile

Ukungena kwesikali se-iron oxide: Ukungena kwesikali se-iron oxide kuyisici esingaphezulu esakheka ngesikhathi sokuginqika okushisayo. Ngemuva kokukhetha, kuvame ukucindezelwa kusimo samachashazi amnyama nemichilo, indawo engaphezulu ilukhuni, ivamise ukuba nokuzwakala kwesandla, futhi ivela ngokungajwayelekile noma ngokujulile. Kuvame ukubangelwa inqubo yokushisa engaphelele, inqubo yokwehlisa kanye nenqubo yokugoqa yokukhetha.

Indawo ye-oksijeni (umdwebo wokwakheka kwezwe ongaphezulu): ibhekisela ekubukekeni okufana nechashazi, umugqa noma umgodi oshiywe ngemva kokuthi isikali se-iron oxide esingaphezulu kwensimbi egoqelwe ngokushisayo. Ukugoqa kucindezelwa ku-matrix, egqanyiswa ngemva kokukhetha. Inomphumela othile ekubukeni, kodwa akuphazamisi ukusebenza.

I-Macular: amabala aphuzi avela engxenyeni noma yonke indawo yebhodi, engakwazi ukumbozwa ngemva kokugcoba, okuthinta ikhwalithi nokubukeka komkhiqizo. Isizathu esiyinhloko siwukuthi umsebenzi ongaphezulu we-strip osanda kuphuma ethangini lokukha uphakeme, amanzi okugeza ayehluleka ukugeza umucu ngendlela evamile, i-spray beam kanye nombhobho wethangi lokuhlanza kuvinjiwe, futhi ama-engeli awalingani.

I-under-pickling: Ingaphezulu le-strip steel linezikali ze-iron oxide zasendaweni ezingasuswanga ngokuhlanzekile nangokwenele, futhi ingaphezulu lepuleti limnyama ngokumpunga, linezikali zezinhlanzi noma ama-ripples amanzi avundlile. Ihlobene nenqubo ye-asidi, ikakhulukazi ngenxa yokuthi ukugxila kwe-asidi akwanele, izinga lokushisa alikho phezulu, umugqa ugijima kakhulu, futhi umugqa awukwazi ukucwiliswa ku-asidi.

Ukukhetha ngokweqile: Ingaphezulu lensimbi ye-strip ngokuvamile limnyama mnyama noma elinsundu ngokumnyama, libonisa ibhlokhi, amachashaza amnyama aluhlaza noma i-macular, futhi ingaphezulu lepuleti ngokuvamile limaholoholo. Isizathu siphambene ne-underpickling.

Ukungcoliswa Kwemvelo

Ukungcola okuyinhloko enqubweni yokukhiqiza amanzi angcolile okuhlanza akhiqizwa inqubo yokugeza amanzi kuwo wonke amazinga, uthuli olukhiqizwa inqubo ye-sandblasting, inkungu ye-hydrogen chloride acid ekhiqizwa inqubo yokukhetha, kanye nemfucuza ekhiqizwa yi-picling, ukuhlanza, phosphating, neutralization kanye nezinqubo zokuvimbela ukugqwala. Uketshezi lwethangi, izinsalela zikadoti, isici sokuhlunga udoti, imiphongolo yempahla eluhlaza kanye nemfucuza yokupakisha, njll. Ukungcola okuyinhloko i-hydrogen chloride, i-pH, i-SS, i-COD, i-BOD?, i-ammonia nitrogen, i-petroleum, njll.

Laser Cleaning

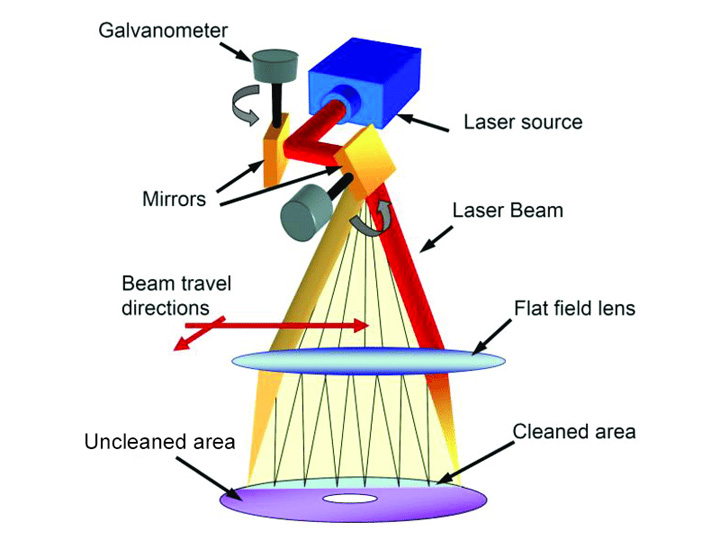

Ukuhlanza Isimiso

Umshini wokuhlanza we-laserukusebenzisa amandla e-laser ukungena endaweni engaphezulu yento. Ama-electron asendaweni adonsa ukudlidliza kwamandla cishe ama-femtoseconds ayi-100, futhi akhiqize i-plasma ebusweni bento. Ngemuva kwama-picosecond angu-7-10, amandla e-electron adluliselwa ku-lattice futhi i-lattice iqala ukudlidliza. Ngemuva kwe-piccosecond, into iqala ukukhiqiza izinga lokushisa elikhulu, futhi izinto zendawo ezikhanyiswa yi-laser ziqala ukushisa, zincibilike futhi zihwamuke, ukuze kufezwe injongo yokuhlanza.

Inqubo Yokuhlanza Nomphumela

Uma kuqhathaniswa nendlela yokukhetha, uhlelo lokuhlanza nge-laser lulula kakhulu, akukho ukwelashwa okudingekayo, futhi umsebenzi wokuhlanza ukususwa kwamafutha, ukukhishwa kwe-oxide layer kanye nokususwa kokugqwala kungenziwa ngesikhathi esifanayo. Vele uvule idivayisi ukuze ukhiphe isibani, bese uyihlanze.

Uhlelo lokuhlanza i-laser lungafinyelela izinga eliphakeme kakhulu lokuhlanza izimboni lezinga le-Sa3, cishe akukho monakalo ebukhuni, i-hydrophilicity kanye ne-hydrophobicity yendawo yezinto ezibonakalayo. Icoliseka kakhulu kune- pickling.

Ubuhle nobubi

Ukugeleza Kwenqubo kanye Nezidingo Zokusebenza

Uma kuqhathaniswa nethuluzi lokukhetha elinezinqubo ezingaphezu kweshumi nambili, isicoci se-laser sizuze inqubo eyenziwe lula futhi ngokuyisisekelo sizuze isinyathelo esisodwa. Kufinyeza kakhulu isikhathi sokuhlanza nokulahlekelwa kwezinto ezibonakalayo.

Indlela yokukhetha inezidingo eziqinile enqubweni yokusebenza: i-workpiece kufanele ihlanjululwe ngokuphelele ukuze kuqinisekiswe ikhwalithi yokususwa kokugqwala; ukugxilwa kwesisombululo se-pickling kulawulwa ukuvimbela ucezu lokusebenza ukuthi lungagqwali ngenxa yokuhlushwa kwe-asidi ngokweqile; izinga lokushisa lilawulwa ngokuvumelana nenqubo yokucacisa ukugwema ukulimala endaweni yokusebenza futhi Imishini ibangela ukugqwala; i-pickling tank kancane kancane ibeka i-sludge, evimbela ipayipi lokushisa nezinye izinto zokulawula, futhi idinga ukususwa njalo; ngaphezu kwalokho, kubalulekile ukunaka isikhathi sokukhetha, ukucindezelwa komjovo, i-sputtering yokusebenza, imishini yokukhipha umoya, njll.

Ukuhlanza i-laser kungathola ukusebenza okufana nobuwula noma ngisho nokusebenza okuzenzakalelayo okungenamuntu ngemva kokusetha amapharamitha ekuqaleni.

Umphumela Wokuhlanza Nokungcola Kwemvelo

Ngaphezu komphumela onamandla wokuhlanza, uhlelo lokuhlanza nge-laser lubuye lube nenzuzo yokubekezelela amaphutha amakhulu.

I-oxygen macular, redness and blackening ngokuvamile kwenzeka ngenxa yamaphutha ekusebenzeni kwendlela yokukhetha, futhi izinga lokwenqatshwa liphezulu.

Ukuhlolwa kwe-laser yokudonsa amanzi kufakazela ukuthi noma ngabe ukuhlanzwa kwe-laser kune-supersaturated, kusene-metallic luster eqinile, futhi akukhiqizi i-hydroxide nokunye ukungcola, okungeke kuthinte izindlela zokucubungula ezilandelayo ezifana nokushisela.

Ngeke kube khona ukungcoliswa kwemvelo okufana noketshezi olulahlwayo kanye ne-slag kuyo yonke inqubo yokuhlanza i-laser, okuyindlela yokuhlanza eluhlaza kakhulu.

Izindleko Zeyunithi VS Izindleko Zokuguqulwa

Ithuluzi lokuqoqa lidinga amakhemikhali njengento esebenzisekayo, ngakho-ke izindleko zeyunithi zihlanganisa ukwehla kwemishini + izindleko zokusetshenziswa.

Umshini wokuhlanza i-laser awudingi izinto ezisetshenziswayo ngaphandle kokuthenga imishini. Izindleko zeyunithi ukwehla kwenani lempahla.

Ngakho-ke, lapho isikali sokuhlanza sikhulu futhi iminyaka iba yinde, ziyancipha izindleko zeyunithi yokuhlanza nge-laser.

Ukwakhiwa komugqa wokukhiqiza i-pickling kudinga izinqubo eziyinkimbinkimbi, futhi isilinganiso sama-pickling agent wezinto ezahlukene zensimbi akufani, ngakho-ke umugqa wokukhiqiza ukuguqulwa udinga izindleko ezinkulu zokuguqulwa, futhi impahla yensimbi kufanele ihlanzwe ngesikhathi esifushane. ayishadile futhi ayikwazi ukushintshwa kalula.

Azikho izindleko zokuguqulwa zokuhlanza i-laser: ngemva kokushintsha imingcele yesofthiwe yomshini ofanayo wokuhlanza, umphumela wokuhlanza ipuleti yensimbi umzuzu owodwa kanye ne-aluminium alloy ngomzuzu olandelayo ungafinyelelwa. Kulula ukuthi amabhizinisi asebenzise ukukhiqizwa okuguquguqukayo kwe-JIT.

Fingqa

Ipuleti le-Pickling linohlelo olubanzi futhi olujulile ekukhiqizeni ukukhiqiza, futhi lidlala indima enhle ekusekelweni kwezimboni. Kodwa-ke, ngokuthuthuka okuqhubekayo kwemboni yokukhiqiza, ukuthuthukiswa kwamandla kanye nokulungiswa kwesakhiwo nakho kwenziwa kancane kancane.

Ngokuthuthukiswa kokuqwashisa kwabantu ngemvelo, uhulumeni kanye nezinkampani zinezidingo eziqinile zokukhetha imigqa yokukhiqiza, futhi amaphethelo enzuzo amabhizinisi ahlobene aya ngokuncipha futhi ngokuncipha. Imvelo jikelele ivuna kakhulu ukuhlanzwa nge-laser.

Mhlawumbe eminyakeni eyishumi ezayo, amashidi okukhetha azoba negama elisha - amashidi okuhlanza laser.