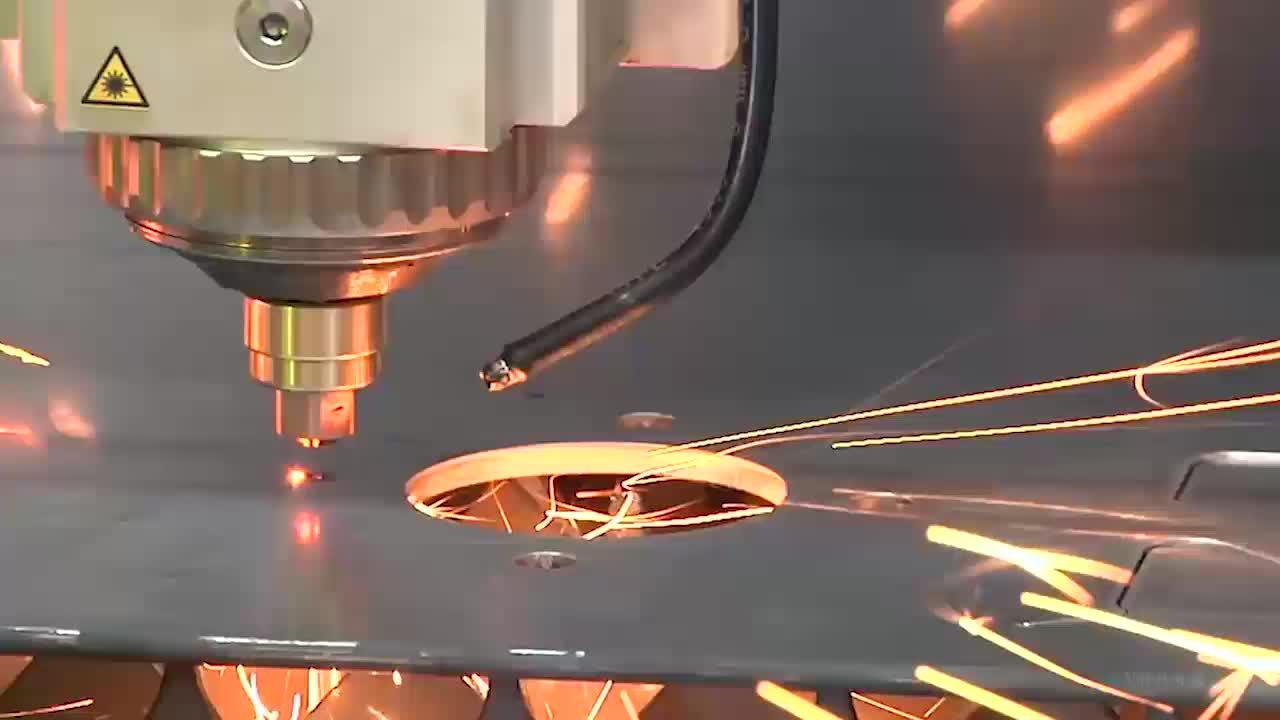

Izici eziyinhloko ezenza umshini wokusika i-laser usebenze yilezi:

1. Usayizi wendawo lapho i-laser beam idlula lapho kugxilwe khona

Indawo encane lapho ugxila ku-laser, enembe kakhulu, ikakhulukazi umfantu omncane, indawo ingafinyelela ku-0.01mm.

2. Ukunemba kwebhentshi lokusebenza kunquma ukuphindaphinda kokusika.

Ukuphakama kokunemba kwebhentshi lokusebenzela, kukhuphuka ukunemba.

3. Ingxenye enkulu, iyancipha ukunemba kanye nomehluko omkhulu.

Njengoba i-laser beam ivuliwe, i-crack nayo ivuliwe. Insimbi engagqwali engu-0.3mm incane kunomgodi ongu-2mm.

4. Izinto ze-workpiece zinethonya elithile ekunembeni kwe-laser cutting.

Ngaphansi kwezimo ezifanayo, insimbi engagqwali inamandla okuhlanza aphezulu kanye nesiphetho esithambile kune-aluminium.

5. Izinga lokusika lomshini wokusika we-laser lihle. Ububanzi bokusika buncane (ngokuvamile bungu-0.1–0.5mm), ukunemba kuphezulu (ngokuvamile, iphutha lembobo emaphakathi ngu-0.1–0.4mm, iphutha lokulinganisa lingu-0.1–0.5mm), futhi ubulukhuni bendawo buwukusisika. okuhle (ngokuvamile, i-Ra ingu-12.5–25μm), izimbobo ngokuvamile zingashiselwa ngaphandle kokucubungula okwengeziwe.