I-Co2 Laser Cutter kanye ne-Engraver ye-MDF/Wood/Acrylic

ISICELO

Umshini wokusika we-laser we-Co2 ungumshini ochwepheshile wokusika nokuqopha ongeyona eyensimbi, ofanele i-acrylic, ibhodi elinemibala ephindwe kabili, isikhumba, indwangu, iphepha, ibhokisi lokupakisha ngokhuni, uqalo, igobolondo, amazinyo endlovu, irabha, imabula nokunye.

I-PARAMETER

| Usayizi Wokusebenza: 600*400mm/600*900mm/1300*900mm//1400*100mm/1600*1000mm | I-Tube Watts: 80W/100W/130W/150W/200W/300W |

| Uhlobo lweLaser: Ishubhu yengilazi evaliwe ye-CO2 | Ikhanda Eligawulayo: Lingashadile |

| Uhlelo lokusebenza: RDC6445G | Umshayeli kanye neMotor: i-stepper noma i-servo |

| Uhlelo Lokupholisa: Ukupholisa amanzi | Isivinini sokusika: 0-600mm/s |

| Isivinini Sokuqopha:0-1200mm/s | Ukunemba Kokubekwe Kabusha: ≤±0.01mm |

| Ubuncane Bezinhlamvu Zosayizi: IsiNgisi: 1mm | Isoftware ehambisanayo: CorelDraw, AutoCAD, Photoshop |

IMINININGWANE

Ithebula plate ukujiya kuyinto5mm, yenza umshini uzinze kakhudlwana, futhi kungabikho ukuguga ngemva kweminyaka eminingi.

Uma sifaka isistimu yesitimela, sisebenzisa izinto zokusebenza zokulinganisa ezichwepheshile ukuze sigcine ileveli yesitimela engu-100%, iqinisekisa ukunemba okuphezulu komshini.

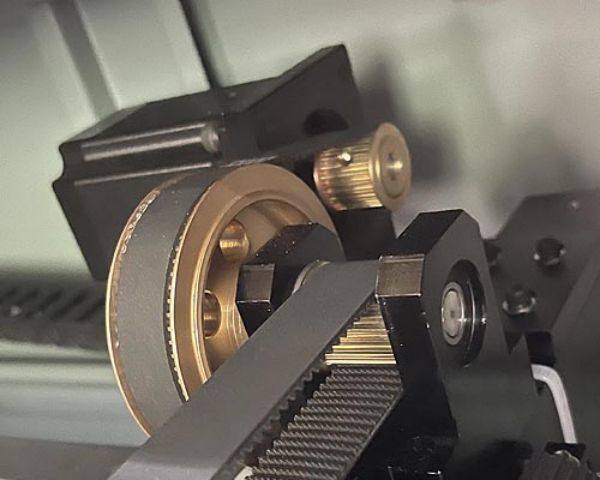

Umshini one-copper pully, uhlala isikhathi eside kunokudonsa kwe-aluminium, amazinyo e-aluminium angasetshenziswa kalula, futhi ukunemba kuzokwehla.

Sakha ipuleti lonogada ngokukhethekile, lingavikela opharetha ekulimaleni kwe-laser ngengozi.

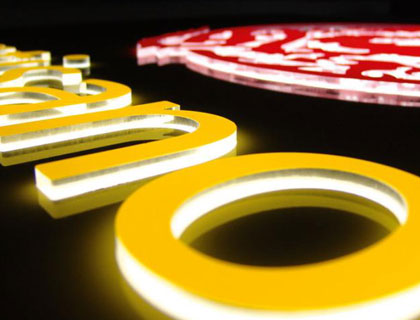

AMAsampuli

IVIDIYO YOKUSEBENZA

IZINKETHO

1. Amakhanda amabili noma amakhanda amane ayatholakala ngokukhetha kwakho, angasebenza ama-pcs amabili noma amane ngesikhathi esisodwa ukuphakamisa ukusebenza kahle.

2. Ithebula eliphansi naphezulu: lilungele izinto eziwugqinsi.

3. I-Rotary: ilungele ibhodlela, inkomishi, nokunye okufanayo.

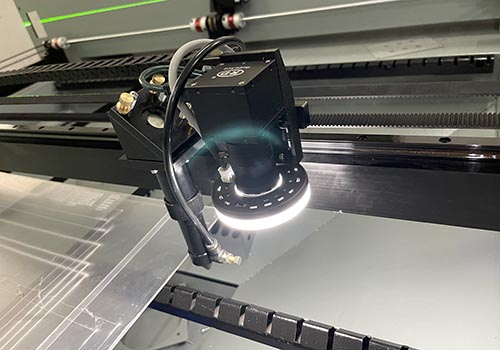

4. Ikhamera: lapho umshini ufaka ikhamera, ingakwazi ukusika ithrekhi, njengokusika ilebula nokuklama.

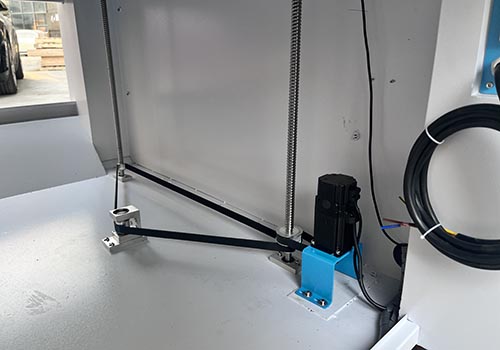

5. Idivayisi yokugxila ezenzakalelayo: ingagxila ngokuzenzakalelayo lapho ukujiya kwezinto kuhlukile, yonga isikhathi sakho.

6. Iyunithi yomlilo: lapho okusika okuvutha umlilo kubamba umlilo, kuzokwenza i-alamu, ungathola ngokushesha futhi ubhekane nayo.

7. Isibani senkomba: sizobonisa isimo sokusebenza esihlukile somshini, sikutshele ukuthi umshini usebenza noma ume lapho ungami ngomshini.

8. Isibani esibomvu: le divayisi ingakubonisa indawo yokusika umshini ngaphambi kokuba umshini uqale ukusika.

Amakhanda amane okusika

Itafula eliphezulu naphansi

I-Rotary

Ikhamera

Ukugxila okuzenzakalelayo

Iyunithi yomlilo

Isibani senkomba

Isibani esibomvu

UKUQEQESHWA

Sihlinzeka ngoqeqesho lwamahhala lobuchwepheshe kuze kube yilapho ikhasimende selikwazi ukusebenzisa okokusebenza ngokujwayelekile.Okuqukethwe okuyinhloko kokuqeqeshwa kungokulandelayo:

1. Ulwazi oluyisisekelo kanye nezimiso laser.

2. Ukwakhiwa kwe-laser, ukusebenza, ukulungiswa kanye nokugcinwa.

3. Isimiso sikagesi, ukusebenza kohlelo lwe-CNC, ukuxilongwa kwephutha jikelele.

4. Inqubo yokusika i-laser.

5. Ukusebenza nokugcinwa kwansuku zonke kwamathuluzi omshini.

6. Ukulungiswa nokugcinwa kwesistimu ye-optical path.

7. Imfundo yokuphepha yokucubungula i-laser.